Good Roundness Polishing Yttria and Zirconia Ceramic Grinding Media Manufacturers From China

Overview Product DescriptionPrincipal characteristic• Good roundness, smooth surface, brightness, high density, high str

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | Yttria Zirconia Grinding Media |

| Bulk Density | 5.98~6.05g/cm3 |

| Packing Density | 3.9 |

| Hv Hardness(Gpa) | 11 |

| Standard Size | 0.4-6.0mm |

| Sphericity | 95% |

| Transport Package | 25kg/Bag/Pallet |

| Specification | 0.4-6.0mm |

| Trademark | firstar |

| Origin | China |

| HS Code | 6909120000 |

| Production Capacity | 3000t/Year |

Product Description

Principal characteristic• Good roundness, smooth surface, brightness, high density, high strength, inert and hardness, perfect grinding medium.• Good stability, strong acid resistance and alkali proof.• Have excellent toughness, strength, impact resistance, not broken.• Minimum of wear and tear on equipments and best grinding media.Application:

• Mining,

• MLCC,

• Titanium Dioxide

• Calcium Carbonate

• Paints, Coatings, Pigments

• Dyes, Inks,Product Parameters

| YTZ yttria zirconia grinding beads properties | ||

| Items | Typical Values | |

| Composition | Wt% | 94.8% ZrO2 |

| 5.2% Y2O3 | ||

| Packing Density | kg/L | 3.7~3.9 |

| Bulk Density | g/cm3 | 5.95~6.0 |

| Hardness (HV) | GPa | >8 |

| Wear loss | (g/kgh) | ≤1.3 |

| Crushing Strength | N(5) | ≥16000 |

| Sphericity | % | ≥95 |

| Standard size | mm | 0.3-30 |

| Packing | ||

| 25kgs | ||

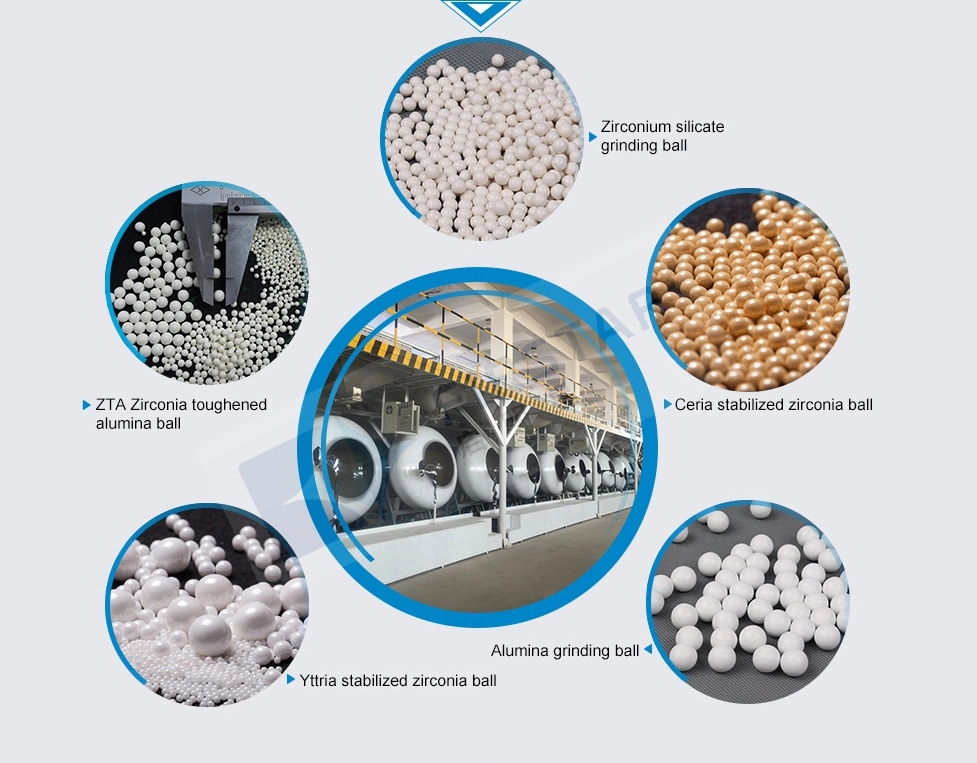

Other Alumina ceramic grinding ball introduction :

Applied for dry grinding , wet grinding ,mineral grinding , quartz grinding , lineston grinding , iron ore grinding , cement grinding , ceramics plants grinding , pigment grinding , mineral ore grinding , breaking platns .

Applied for ball mill,grinding machine , pot mill , librating mill , pebble mill , Attrition Mill,rod mill , grinding mill , grinding machine , ball grinding mill

Size:0.5mm -60mm

Other grinding ball like alumina grinding ball itroduced :

1: 92% Medium alumina grinding ball series :

A) Al2O3 : 92%

B) Mosh hardness: 8 grade

C) Color : white or brown

2: 75% Medium alumina grinding ball series :

A) Al2O3 : 75%

B) Mosh hardness: 8 grade

C) Bulk density ≥ 3.15 g/cm3

D) Color : white or brown

3: 60% Medium alumina grinding ball series :

A) Al2O3 : 60%

B) Mosh hardness: 7 grade

C) Bulk density ≥ 2.8 g/cm3

D) Color : white or brown

Detailed Photos

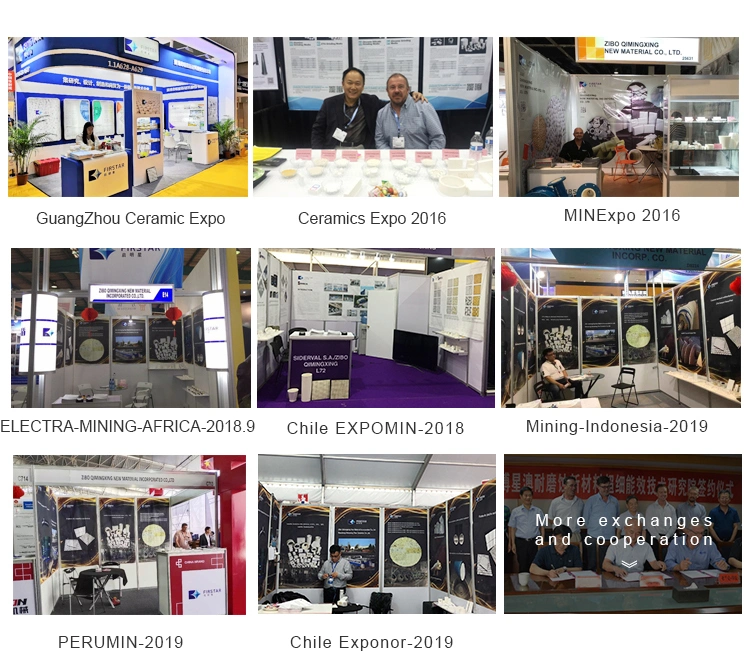

Company Profile

Qimingxing offer quality wear and Ant- impact ceramics, in combination with our experienced and competent staff, ensure the increased efficiency and service life of all equipments and materials to which they are applied. - Established Ultrafine Energy Efficiency Technology Research Institute - Increase lifespan of wearable parts - New improved technology and products - Minimal downtime to minimize delays in production - Variety of wear combating options available as a one stop solution - Strong focus on product innovation supported by Chinese Academy of Sciences. - Customized application techniques to suite any wear problem

OTHER HOT SALE

More Abrasion ceramics products : abrasion ceramics , Alumina ceramics , wear resistant ceramics , alumina pipe liner , ceramic tube , alumina cylinder pipe , wear resistant alumina plate , abrasion ceramic tile , abrasive alumina sheet , friction plain tile , abrasion weldable tile , rubber backed ceramic liner , ceramic composite linings , alumina mosaic sheet , ceramic taper tile for pipe sleeve , ceramic ladder tile for pipe steel , engineering ceramics equipment , pre-fabricated pipe sleeve ,wear resistant bending pipe , abrasion materials

Packaging & ShippingFAQQ: What is your experience in your products?

A: We have 22 years experience in this industry line. We are professional manufacturer in this area

Q: What is your MOQ?

A: The MOQ is different as per different products, for example, 1 Ton for ceramic ball

Q: Can you accept small quantity sample order before production?

A: Yes, we can offer sample for your testing first

Q: Can you provide free sample?

A: Yes, within 1kg

Q: What is your production time?

A: We have large stock for standard products. Normally within 7-10days after receipt the deposit

Q: What are your payment terms?

A: T/T, L/C, Western Union